Empowering New Energy, Supporting Every Step

We deliver full-process solutions for the new energy industry—from materials and cells to full-line setup—empowering clients at every step toward sustainable success.

ONE-STOP

SOLUTIONS

We offer complete solutions covering materials, cells, PACK, and full line setup to meet diverse needs.

TOP INDUSTRY PARTNERSHIPS

We work with industry leaders like CATL, BYD, and EVE, earning trust with reliable equipment and services.

COMPREHENSIVE TECHNICAL SUPPORT

From project launch to after-sales, we provide lifetime service and support to ensure long-term stability.

SOLUTION

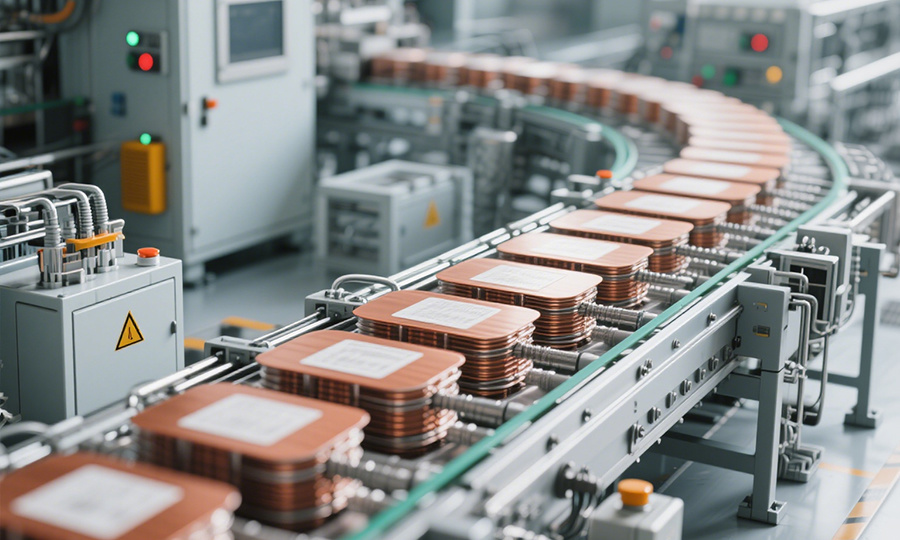

Creating Efficient and Smart New Energy Production Lines to Enhance Client Market Competitiveness

ABOUT GNPN

Driving a Green Future, Empowering Smart Growth

Guangdong GNPN New Energy Technology Co., Ltd. focuses on providing complete solutions, lifetime services and full-service services for new energy industries such as lithium-ion batteries and sodium-ion batteries, including the construction and technical services of production lines for cathode and anode materials, battery cells, PACK, copper and aluminum batteries, etc.

We have earned a good reputation by providing professional services and reliable quality equipment to well-known new energy industry manufacturers in China (including CATL, BYD, Everview Lithium Energy, Huayou Cobalt, BTR, Shanshan, etc.). Our core business focuses on manufacturing complete solutions for the new energy industry.

Partner

Cooperated with leading enterprises in more than 50 industries

Solution

More than 200 solutions have been provided

Country and region

The project covers more than 20 countries and regions

R&D investment

Annual Technical R&D Investment of 50,000,000

FACTORY STRENGTH

Leveraging strong production capacity and technical advantages, our factory efficiently achieves large-scale production, ensuring that every step from design to delivery meets international quality standards.

View Our FactoryPRODUCT

Crafting Leading Projects Across Industries, Providing Clients with Innovative and Efficient Solutions

BLOG & EVENT

Stay Informed with Company News, Key Insights into the New Energy Sector, and Our Latest Projects and Partnerships

2026-03-07

Understanding VC Mixers: A Key Component in Advanced Manufacturing

--- In the realm of manufacturing and processing machinery, VC mixers, or Variable Consistency mixers, play a pivotal role in ensuring material quality and consistency during production. These advanced mixing systems are designed to accommodate a variety of materials, offering versatility and adaptability in various manufacturing processes. Understanding the intricacies of VC mixers can significan

2026-03-06

Maximizing Productivity: Key Features of Auxiliary Systems for Battery Lines

Maximizing Productivity: Key Features of Auxiliary Systems for Battery Lines In the fast-evolving world of battery manufacturing, the demand for efficient and reliable production processes has never been greater. As industries pivot towards renewable energy solutions, optimizing battery production lines becomes a crucial aspect of meeting market needs. Auxiliary systems play a pivotal role in enha

2026-03-05

Understanding Size Reduction Equipment: A Key Component in Manufacturing Processes

Size reduction equipment is essential in various manufacturing sectors, including food processing, pharmaceuticals, and materials recycling. This equipment is designed to reduce the size of raw materials, facilitating easier handling, transportation, and further processing. The primary goal of size reduction is to convert bulk materials into smaller, manageable pieces, which can lead to improved p