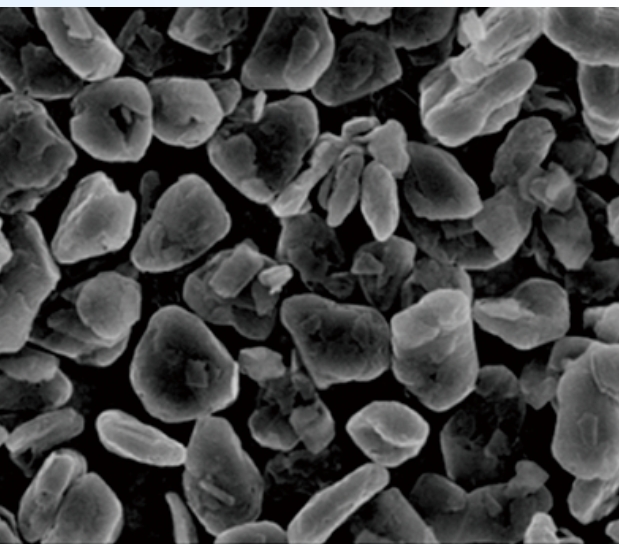

LFP Cathode Material

May 07,2025

The indirect co-precipitation method involves first preparing a transition metal salt solution with a stoichiometric ratio, then adding a precipitating agent to obtain a ternary mixed co-precipitation precursor.

D50:

0.6-1.6

Tap D g/cm³:

≥2.35

(Cap)mAh/g:

>150

(ICE)%:

≥95.5

Application:

Mid-Low Tier EV Energy Storage Station & Electric Two-Wheeler

LFP cathode materials

- The indirect co-precipitation method involves first preparing a transition metal salt solution with a stoichiometric ratio, then adding a precipitating agent to obtain a ternary mixed co-precipitation precursor. After filtration, washing, and drying, it is mixed and sintered with lithium salts. Or, before filtration, the lithium salt can be added to the solution of the mixed co-precipitated precursor, evaporated or freeze-dried, and then subjected to high-temperature sintering.

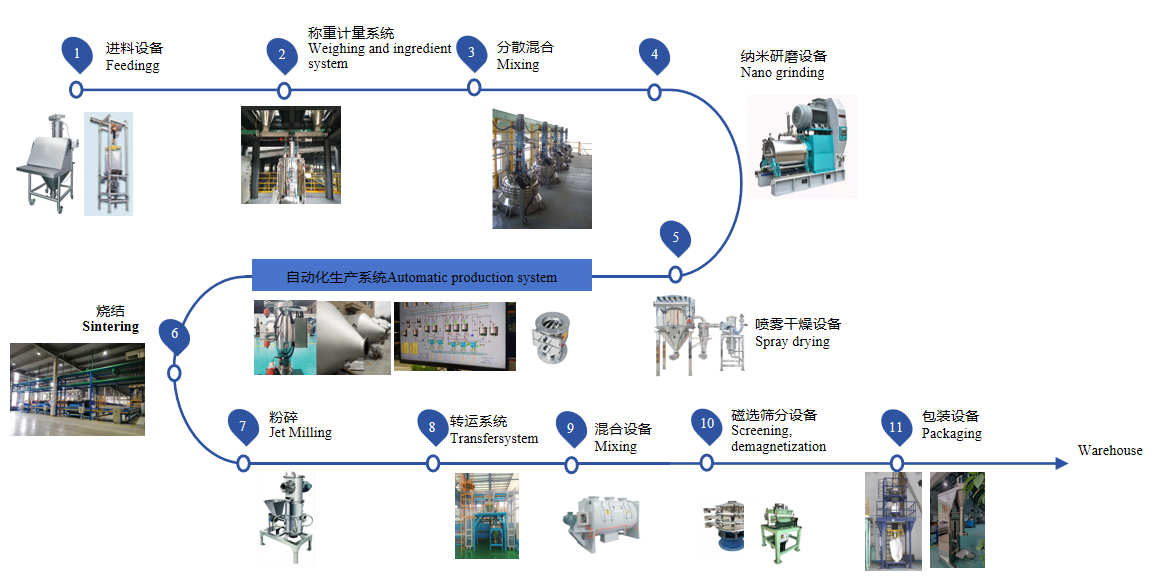

- Mixing

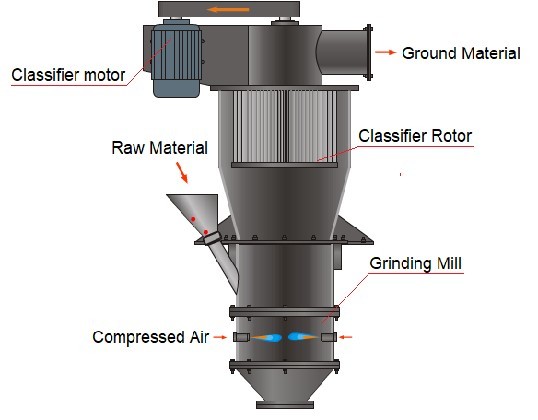

- Nano Grinding

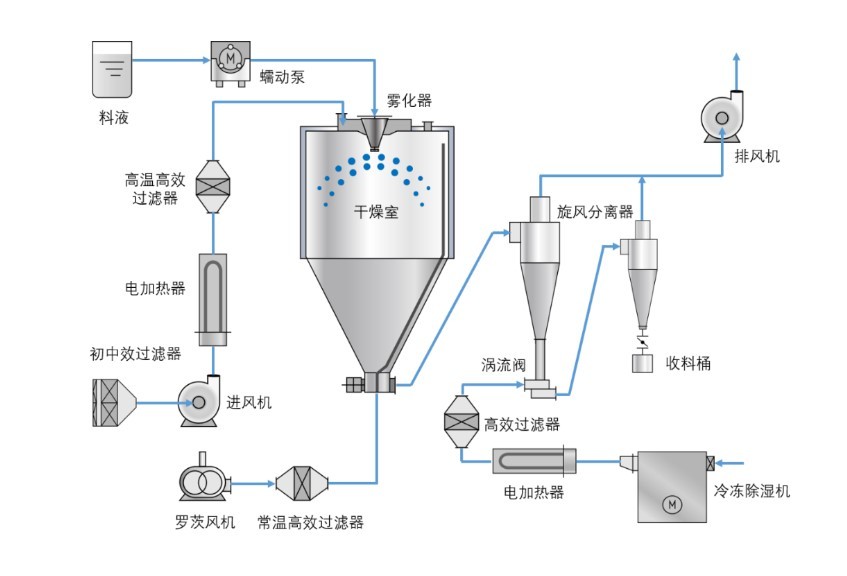

- Spray Drying

- Sintering

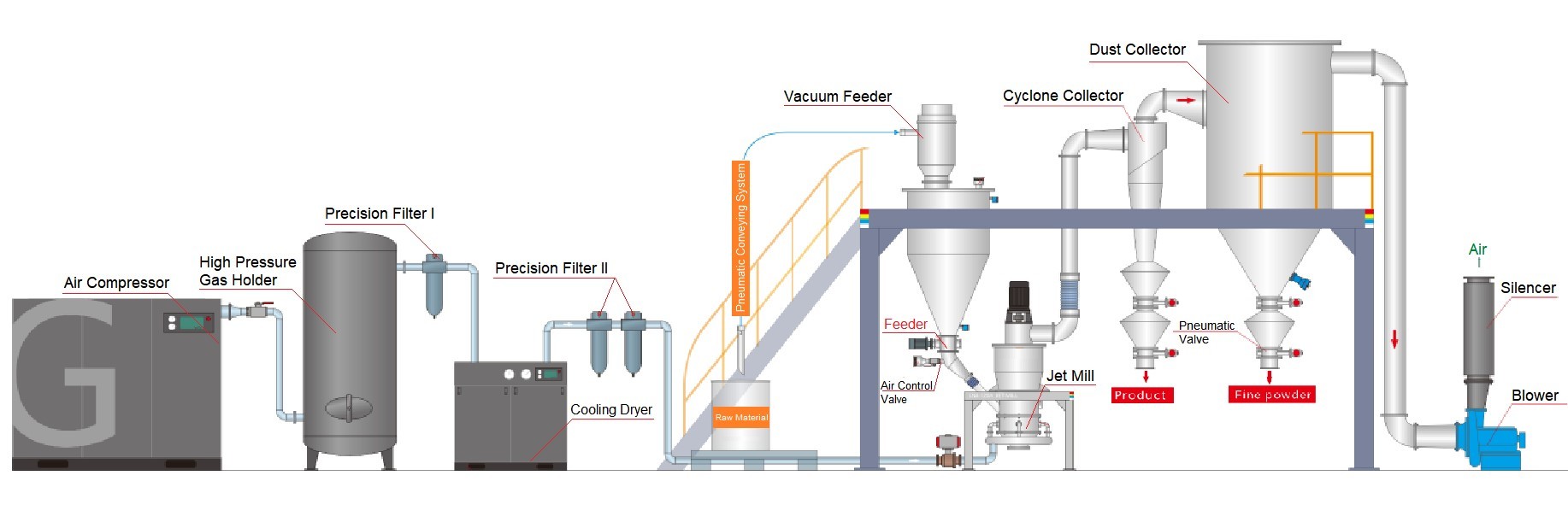

- Jet milling

- Product Processing

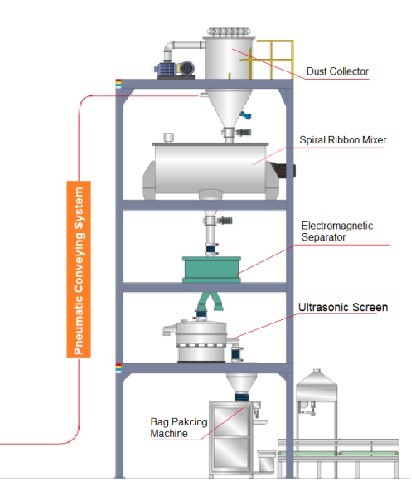

Typical Flowchart for LFP Cathode

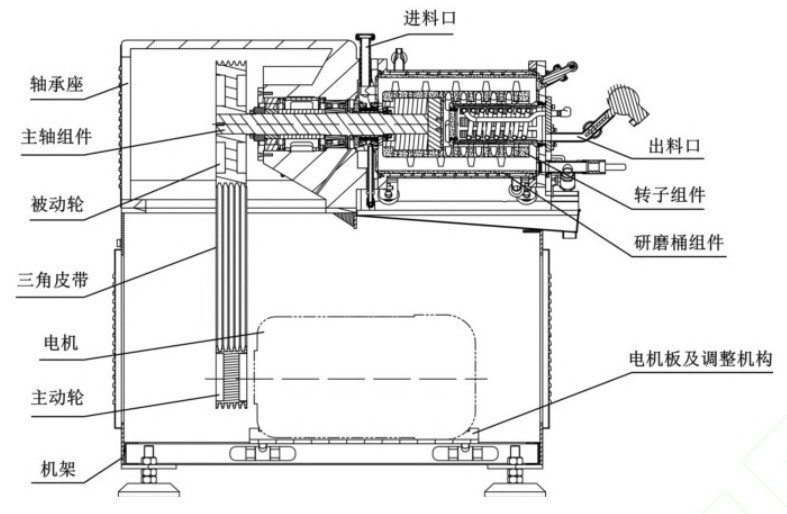

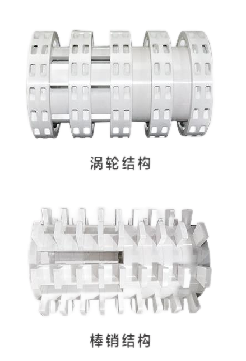

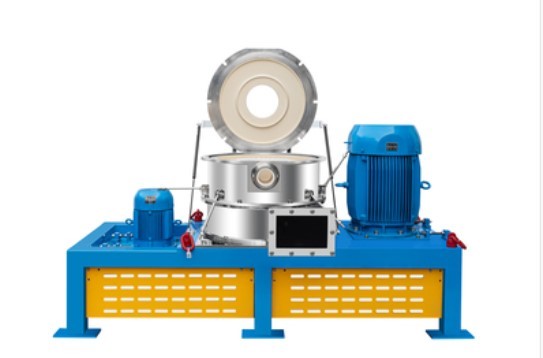

Bead Mill

- The sand mill is a key equipment specifically designed for the wet-process nano-grinding of lithium iron phosphate (LFP) cathode materials. Its core function is to refine material particles to the nanoscale (typically targeting a particle size of D50 ≤ 0.5 μm) through high-speed shearing and the physical action of grinding media (such as zirconia beads), thereby enhancing the battery's rate performance and cycle life.

Spray Drying

- Slurry pumped into the spray drying chamber is atomized and granulated through the nozzle or high-speed rotatingatomizing disc. After continuous contact with hot air, the atomized liquid is instantly dried at high temperatures to form powders. Most powders are collected by the discharge port at the bottom of the chamber. Exhaust gas and tiny dust are separated using flters, cycloneseparators, and others. The exhaust fan outlet can also beequipped with a secondary dust removal device.

Sintering

- During the sintering process, trivalent iron (Fe³⁺) in ferric phosphate (FePO₄) is reduced to divalent iron (Fe²⁺) in lithium iron phosphate (LiFePO₄). At high temperatures, carbon acts as a reducing agent due to its reducibility. Glucose, when uniformly mixed via ball milling, forms a carbon coating. Under an inert atmosphere, it carbonizes into a conductive carbon layer on the material surface, enhancing electrochemical performance. This process is typically conducted in a nitrogen-protected roller hearth kiln, with a sintering cycle of 20 hours at 780°C.

Jet Milling

- Jet Mill is a device as using multiple nozzles to form sonic speed air flow to perform ultrarfine pulverizing. The ground materials will be brought to high-efficient turbine classifier, the coarser particles will be swirled back to grinding chamber for further grinding.

Product processing

- Product processing & Warehouse: the material undergoes mixing, sieving, and magnetic separation at ambient temperature to remove oversized particles and magnetic impurities. After passing quality control tests, it is packaged according to customer specifications and stored in the finished goods warehouse.

Previous

Previous:

MORE PROJECTS

Natural Graphite Anode Material

Natural graphite, a carbon-based mineral with a layered hexagonal crystal structure, is a widely used anode material due to its high theoretical capacity (~372 mAh/g), low cost, and abundant reserves.

The indirect co-precipitation method involves first preparing a transition metal salt solution with a stoichiometric ratio, then adding a precipitating agent to obtain a ternary mixed co-precipitation precursor.

The indirect co-precipitation method involves first preparing a transition metal salt solution with a stoichiometric ratio, then adding a precipitating agent to obtain a ternary mixed co-precipitation precursor.

Silicon-carbon anode materials are composed of nano-scale silicon particles (Si, 20-200nm) compounded with carbon matrices (graphite/CNTs/graphene).