NCM/NCA Cathonde Materials

May 06,2025

D50:

3.60-4.60

Tap D g/cm³:

≥1.80

(Cap)mAh/g:

177.0-182.0

(ICE)%:

≥86.0

Application:

Premium Electric Vehicle & Premium Consumer Electronics Modular Energy Storage System

NCM/NCA cathode materials

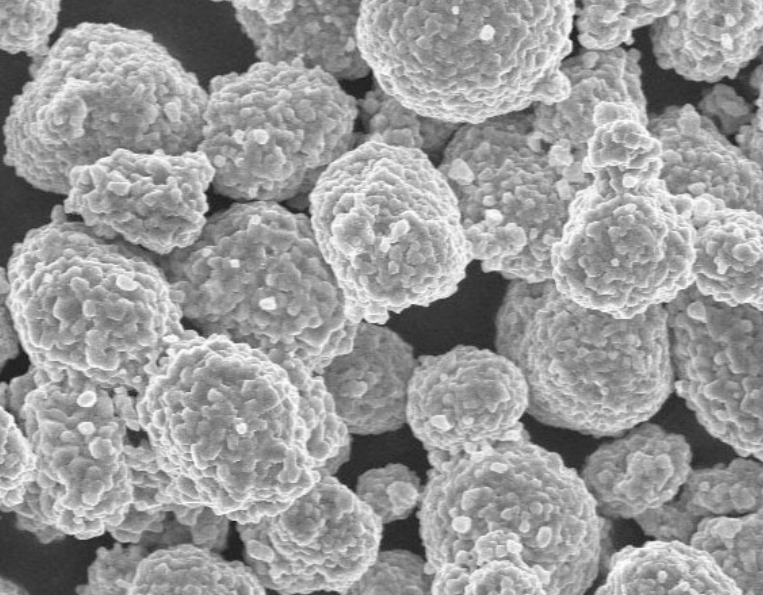

The indirect co-precipitation method involves first preparing a transition metal salt solution with a stoichiometric ratio, then adding a precipitating agent to obtain a ternary mixed co-precipitation precursor. After filtration, washing, and drying, it is mixed and sintered with lithium salts. Or, before filtration, the lithium salt can be added to the solution of the mixed co-precipitated precursor, evaporated or freeze-dried, and then subjected to high-temperature sintering.

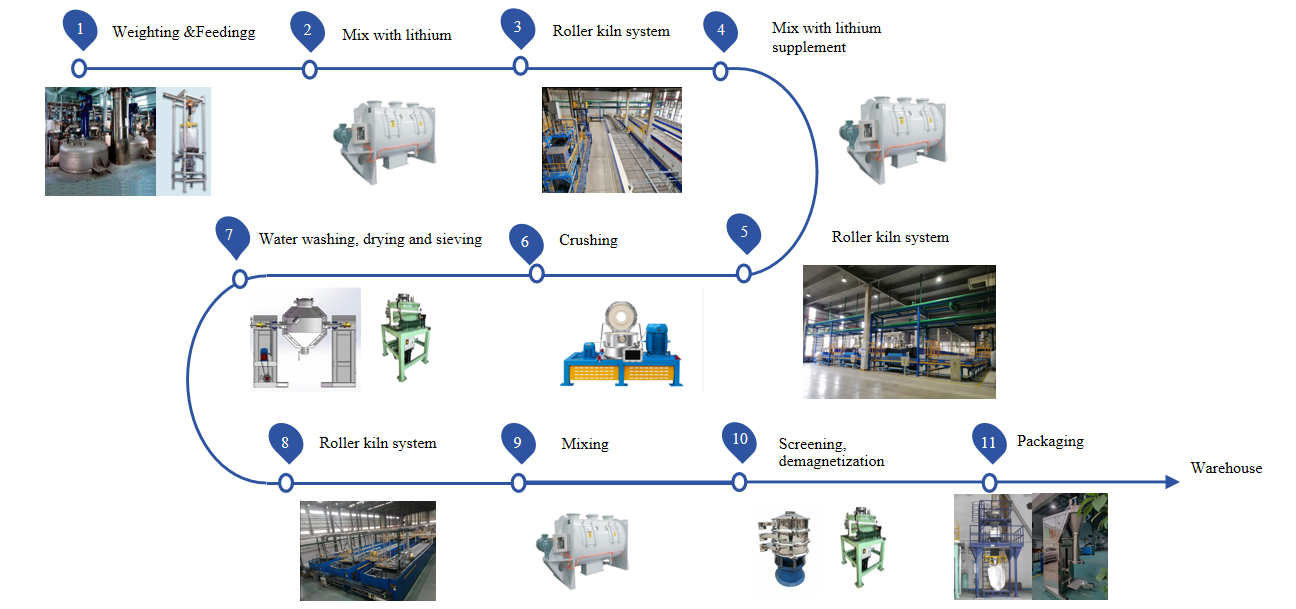

Typical Flowchart for NCM Cathode

Weight Batching-

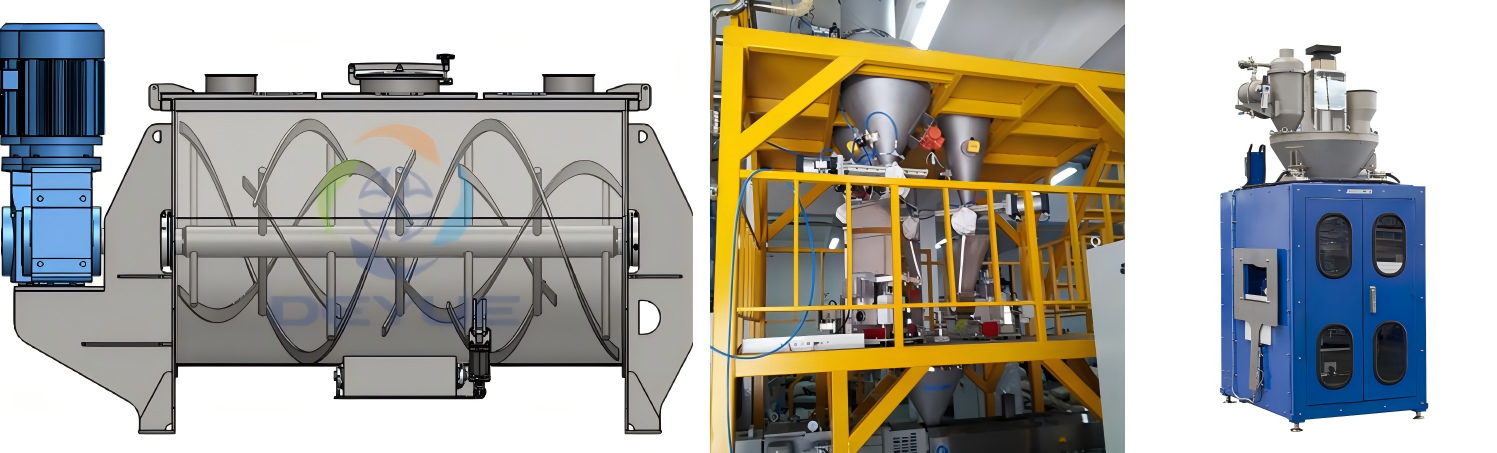

The precursor and lithium source are mixed in a molar ratio, homogenized in a mixer, and transferred into saggers using a loading machine.

Sintering Process

1st Sintering

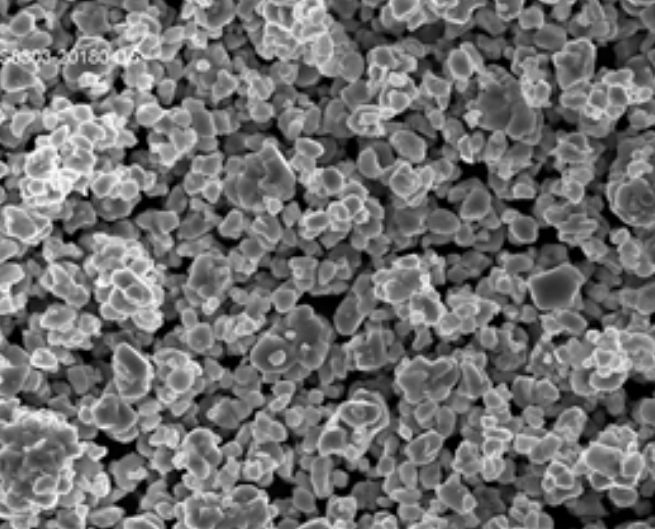

- The primary sintering (pre-sintering) is a critical step in the preparation of ternary cathode materials. During this stage, the nickel-cobalt-manganese (NCM) precursor and lithium source undergo reaction at elevated temperatures to remove moisture and volatile impurities from the precursor-lithium salt mixture, while initially forming a layered crystal structure.

-Temperature: NCM: 750 ~ 850 ℃, NCA: 700 ~ 800 ℃.

-Time: 10 ~ 15 hours.

-The atmosphere: air or oxygen (O ₂) (maintain Ni3⁺ high state).

-Products: preliminary cambium-like structure.

2nd Sintering

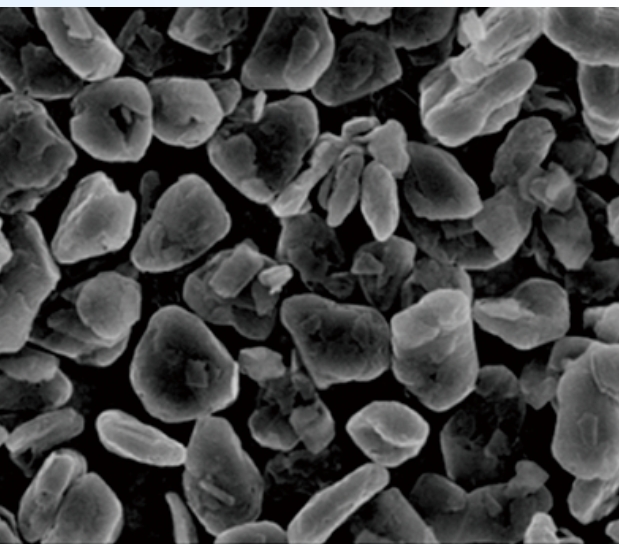

- The second sintering is to further improve the performance of the material,

-Temperature: NCM: 850 ~ 950 ℃, NCA: 800 ~ 900 ℃,

-Time: 8 to 12 hours,

-Atmosphere: hyperbaric oxygen (PO ₂ = 0.3 ~ 0.5 ATM),

-Effect: reduce the cation mixed, improve the degree of crystallinity.

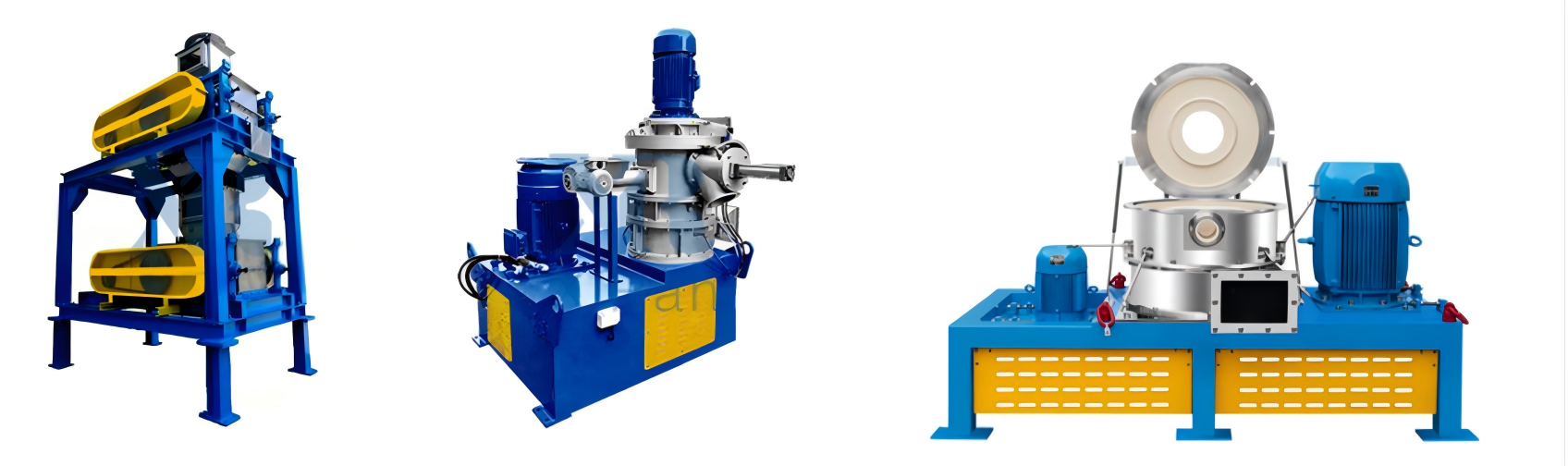

Water washing and drying

- After secondary sintering, the product is crushed using a roller crusher and mechanical mill, then subjected to surface modification via a wet coating process. Residual lithium compounds are removed by water washing to reduce alkalinity, followed by centrifugation and drying. The material is then transferred to the third sintering kiln.

3rd Sintering

- The third sintering is deep stabilization and functional modification, and it can also be used for coating modification.

-Temperature: NCM: 600~750℃, NCA: 700~800℃,

-Time: NCM:4 to 8 hours, NCA:6 to 10 hours,

-Atmosphere: NCM:O₂/N₂ mixed gas, NCA:Low pressure O₂,(0.1~0.3 atm)

-Effect: reduce the cation mixed, improve the degree of crystallinity

Product processing

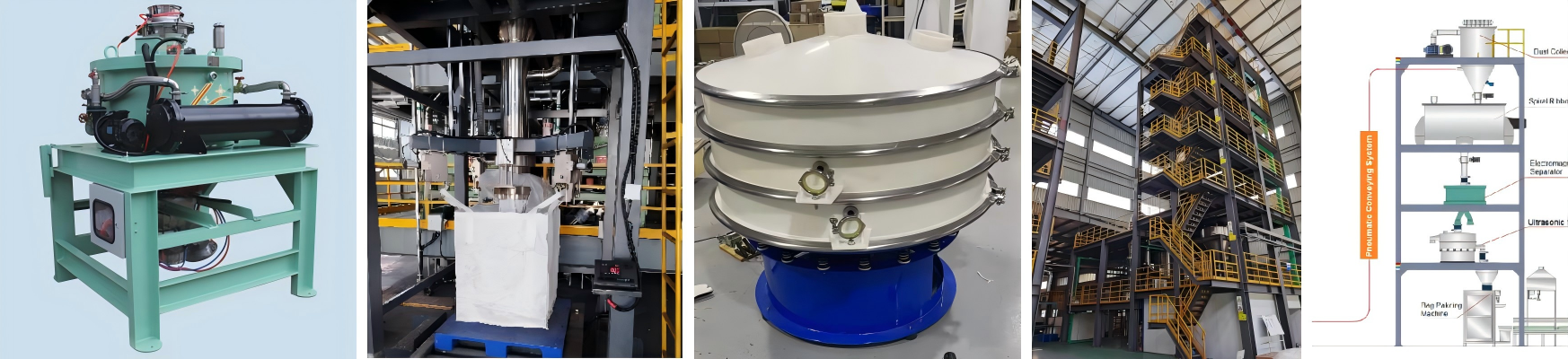

Product processing & Warehouse: the material undergoes mixing, sieving, and magnetic separation at ambient temperature to remove oversized particles and magnetic impurities. After passing quality control tests, it is packaged according to customer specifications and stored in the finished goods warehouse.

Previous

Next

Previous:

Next:

MORE PROJECTS

Natural Graphite Anode Material