Si/C Anode Materials

May 06,2025

D50:

6.0±1.0

Tap D g/cm³:

1.20±0.10

(Cap)mAh/g:

1680±50

(ICE)%:

77.0±1.0

Application:

Mid-Range Smartphone & Drone Battery / UAV Battery & Entry-Level Electric Vehicle (EV)

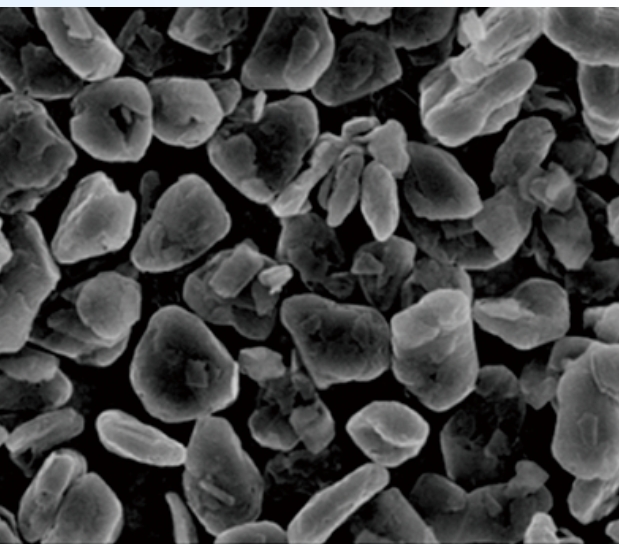

Si/C anode materials

Silicon-carbon anode materials are composed of nano-scale silicon particles (Si, 20-200nm) compounded with carbon matrices (graphite/CNTs/graphene). Based on production processes, they are categorized into two technical routes:

Ball-Milling Method

- Process:

Si+C forms Si/C composite via high−energy ball milling

-Particle size: D50 <500nm

-Silicon content: 5-15wt%

-Conductivity: 10-100 S/cm

- Advantages

-Low cost (~¥80,000/ton)

-Simple process (compatible with existing graphite production lines)

- Challenges:

-High volume expansion (~300%)

-Limited cycle life (500-600 cycles @80% capacity retention

Nanosizing

- During grinding, the rotor and zirconia beads generate intense impact forces (F=ma) and shear forces (τ=μdydv) through high-speed rotation effectively pulverizing and dispersing the Si/C anode material. The collisions and friction between zirconia beads (0.03-0.1 mm diameter) and Si/C particles progressively reduce particle size to D50 <100 nm while ensuring uniform dispersion in the liquid medium.As grinding proceeds, internal temperature rises (ΔT ≈15-25°C above ambient), necessitating real-time cooling via a dynamic cooling system to maintain temperature below 40°C. This is critical to:

1.Preserve material properties (e.g., prevent pitch degradation)

2.Ensure stable operation (avoid thermal expansion-induced equipment stress).

- The system monitors temperature through embedded sensors (accuracy ±0.5°C) and adjusts coolant flow (e.g., 10-20 L/min) automatically. After achieving target particle size (verified by laser diffraction), the homogenized slurry is discharged through the outlet valve for subsequent carbonization

Spray Drying( (ball milled Si/C)

- During grinding, the rotor and zirconia beads generate intense impact forces (F=ma) and shear forces (τ=μdydv) through high-speed rotation effectively pulverizing and dispersing the Si/C anode material. The collisions and friction between zirconia beads (0.03-0.1 mm diameter) and Si/C particles progressively reduce particle size to D50 <100 nm while ensuring uniform dispersion in the liquid medium.As grinding proceeds, internal temperature rises (ΔT ≈15-25°C above ambient), necessitating real-time cooling via a dynamic cooling system to maintain temperature below 40°C. This is critical to:

1.Preserve material properties (e.g., prevent pitch degradation)

2.Ensure stable operation (avoid thermal expansion-induced equipment stress).

- The system monitors temperature through embedded sensors (accuracy ±0.5°C) and adjusts coolant flow (e.g., 10-20 L/min) automatically. After achieving target particle size (verified by laser diffraction), the homogenized slurry is discharged through the outlet valve for subsequent carbonization

Carbonization

Carbonization: graphitized artificial graphite or natural graphite is uniformly mixed with pitch (pre-crushed to a specific particle size using specialized equipment) at a defined ratio in a high-speed mixer. The mixture is then transferred to a nitrogen-protected kiln for high-temperature carbonization at 1,200°C, where the pitch undergoes pyrolysis to form a carbon coating on the graphite surface.

Chemical Vapor Deposition (CVD) Method

- Process:

SiH4(g) deposits on porous carbon to form Si@C core

−shell structure

-Silicon layer thickness: 5

-20nm -Porosity: 30-50% -ICE: 85-89%

- Advantages:

-Superior performance:Capacity: 1,500-2,000 mAh/g

-Expansion rate: <100%

-Cycle life: 1,000+ cycles

- Challenges:

-High equipment cost (CVD reactors ~¥2M/unit)

-Silicon precursor cost (SiH₄: ¥50,000-100,000/ton in 2025)

Fluidized Bed

A fluidized bed reactor suspends silicon/carbon particles in a high-velocity gas stream (e.g., N2 or Ar), enabling uniform chemical vapor deposition (CVD) of silicon from precursors like silane (SiH4) and carbon coating from acetylene (C2H2)

1. Fluidization: Porous carbon powder (D50: 10–50μm) is fluidized via gas distribution plates (velocity: 0.1–1 m/s).

2. Silicon Deposition: SiH4 decomposes at 500–800°C, forming nano-silicon (5–20nm) within carbon pores

3. Carbon Coating: Secondary C2H2 cracking at 700–1000°C creates 2–5nm conductive carbon layers.

Previous

Next

Previous:

Next:

MORE PROJECTS

Natural Graphite Anode Material