Silicon Monoxide

May 06,2025

D50:

6.0±1.0

Tap D g/cm³:

1.20±0.10

(Cap)mAh/g:

1680±50

(ICE)%:

77.0±1.0

Application:

Consumer Electronics & Entry-Level Electric Vehicle (EV) & Energy Storage System (ESS)

Silicon Monoxide

Silicon monoxide anode materials are primarily composed of silicon monoxide (SiOx, where 0<x<2) compounded with carbon materials. Based on different preparation processes, they are categorized into three generations:

| Comparative Summary | |||

| Parameter | Conventional SiOx | Pre-Li SiOx | Pre-Mg SiOx |

| Capacity (mAh/g) | 1,200-1,500 | 1,300-1,700 | ~1,300 |

| ICE (%) | 70-75 | 85-90 | 84-85 |

| Expansion(%) | ~150 | ~140 | ~120 |

| Cost (¥/ton) | ~100,000 | ~200,000 | ~150,000 |

| Applications | TESLA | Samsung SDl | Shin-Etsu |

1st Gen:Conventional SiOx

- Amorphous silicon suboxide (SiOx, 0<x<2) with nano-Si domains dispersed in a SiO₂ matrix, synthesized via high-temperature vapor deposition followed by rapid quenching.

- The standard mass production process involves:

1. Raw Material Reaction: Si+SiO 2> SiOx (vapor). Reaction conducted in vacuum furnaces with precise temperature control (±5°C), oxygen content (x≈1) controlled by Si/SiO₂ ratio (typically 1:1 to 1:1.2)

2. Gas Condensation: Rapid quenching (cooling rate >100°C/s) forms amorphous SiOx precursor

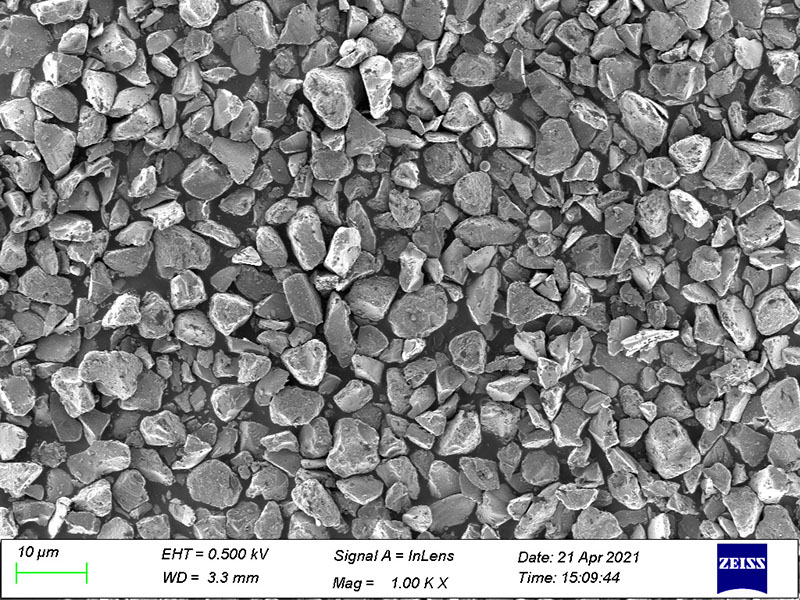

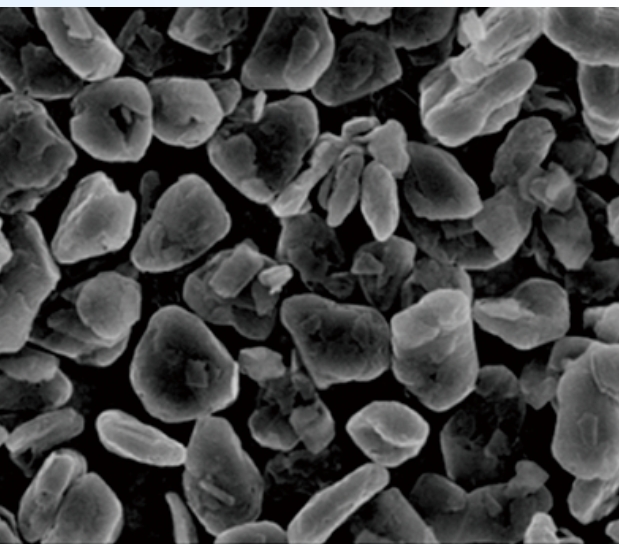

3. Mechanical Processing: Coarse crushing → Jet milling to D50 <5 μm, maintains nano-Si domain size (2-10 nm) within SiO₂

4. Carbon Coating: CVD at 600-1050°C with C₂H₄/CH₄ gas, forms 5-20 nm conductive carbon layer (resistivity <10 Ω·cm

- Key Properties:

1. Capacity: 1,600–2,600 mAh/g (theoretical), ~1,200–1,500 mAh/g (practical)

2. Volume expansion: ~150% (vs. 300% for pure Si)3

3. ICE (Initial Coulombic Efficiency): ~70–75% due to irreversible Li₂O/Li₄SiO₄ formation

- Applications: Blended with graphite (5–20% SiOx) in EVs (e.g., Tesla 4680 cells) to boost energy density

2nd Gen Pre-lithiated SiOx

- SiOx pre-doped with lithium via chemical/electrochemical methods to compensate for initial Li loss.

- Advantages:

1. ICE: Improved to 85–90% (vs. 70% for conventional SiOx)

2. Capacity: 1,300–1,700 mAh/g with enhanced cycling stability (83% retention after 200 cycles)

3. Mechanism: Pre-embedded Li forms stable Li-Si alloys, reducing SEI degradation

- Challenges: High cost (~¥200,000/ton) and complex synthesis (e.g., controlled Li vapor deposition)

- Industrial Status: Adopted by Samsung SDI and CATL for high-end EVs

3rd Gen Pre-magnesiated SiO

- SiOx modified with Mg doping (e.g., SiMgyOx) via vapor-phase reaction.

- Performance:

1. ICE: ~85% (e.g., 84.9% at 750°C Mg vapor deposition)

2. Capacity: ~1,300 mAh/g with reduced expansion (~120%)

3. Stability: MgSiO₃/Li₄SiO₄ phases buffer volume changes

- Market Outlook: Players: Samsung, Shin-Etsu (Japan);

- Challenges: Scalability and cost (Mg purity >99.9% required)

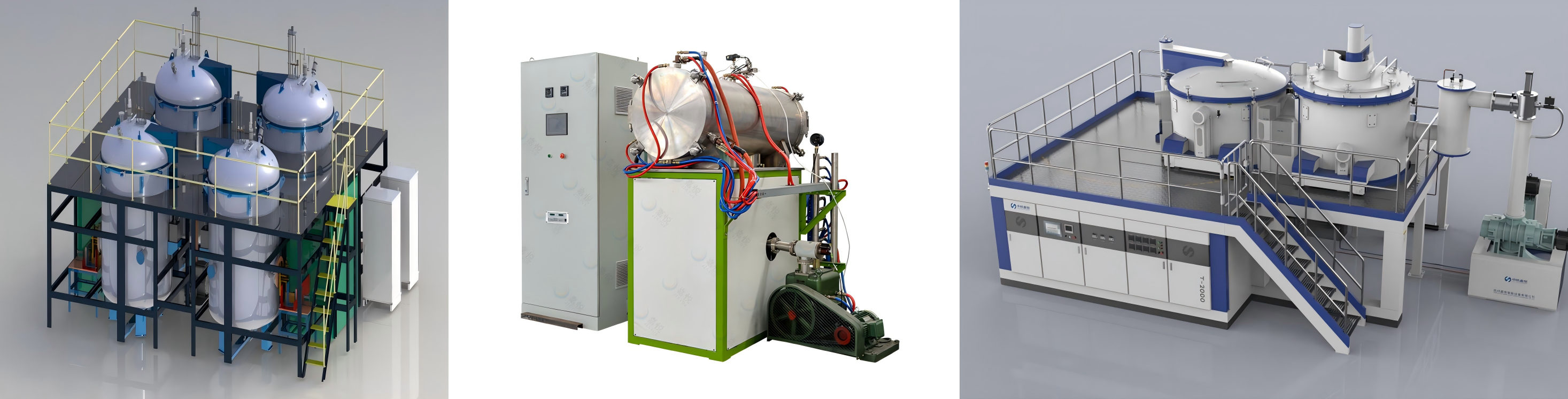

Silicon monoxide reactor (SiO)

Vacumn furnance is mainly used for high-temperature reaction preparation and collection of silicon monoxide, and also has the function of a general high-temperature atmosphere furnace. The equipment consists of the furnace body, furnace door and its locking device, heating system, charging and discharging system, vacuum system, electrical control system, water cooling system, transformer, and connecting cables.

Crushing & Grinding

Jet Mill is a device as using multiple nozzles to form sonic speed air flow to perform ultrarfine pulverizing. The ground materials will be brought to high-efficient turbine classifier, the coarser particles will be swirled back to grinding chamber for further grinding.

CVD Carbon Coating

Rotary kiln employing chemical vapor deposition (CVD) to uniformly coat silicon monoxide (SiOx) particles with conductive carbon layers, enhancing electrochemical performance in lithium-ion batteries.

Previous

Previous:

MORE PROJECTS

Natural Graphite Anode Material