Natural Graphite Anode Material

May 08,2025

D50:

15.0-18.0

Tap D g/cm³:

≥1.55

(Cap)mAh/g:

≥358

(ICE)%:

≥94.0

Application:

3C Consumer Electronics & Home Energy Storage Systems

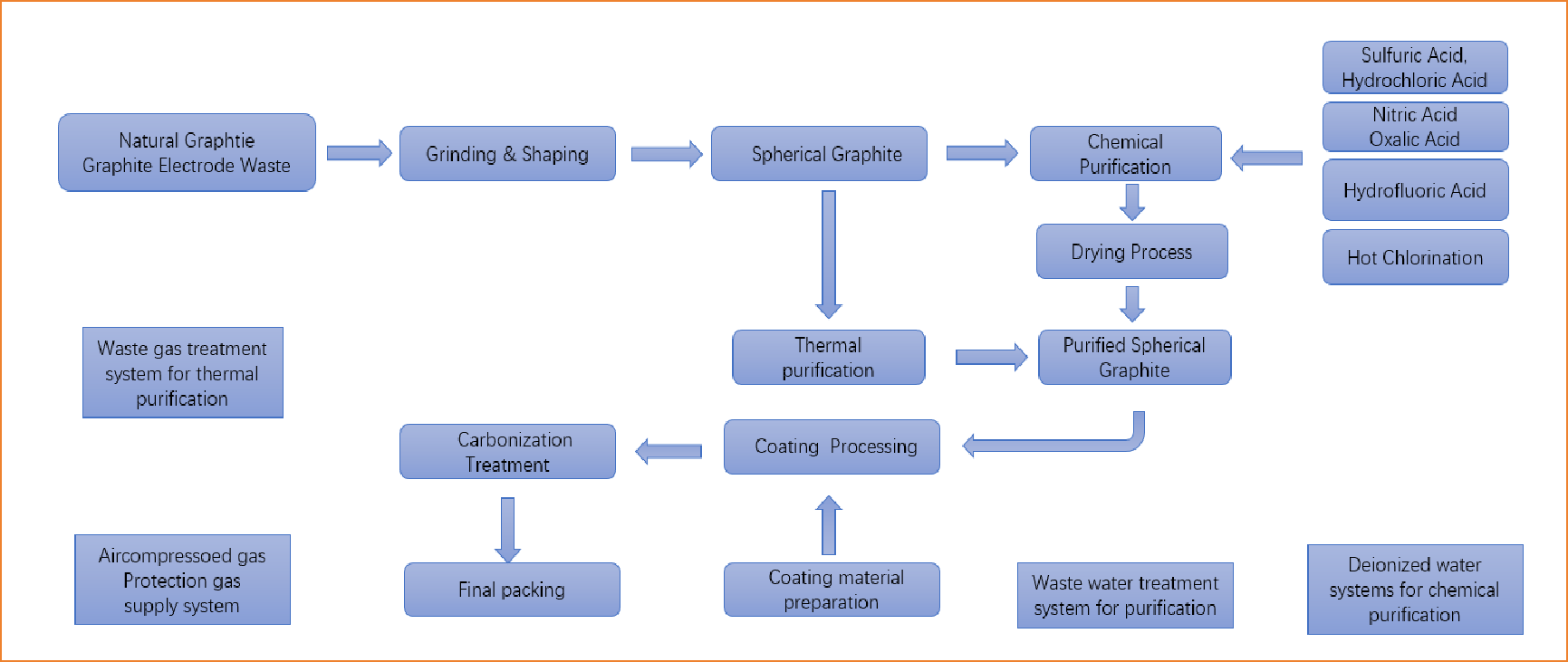

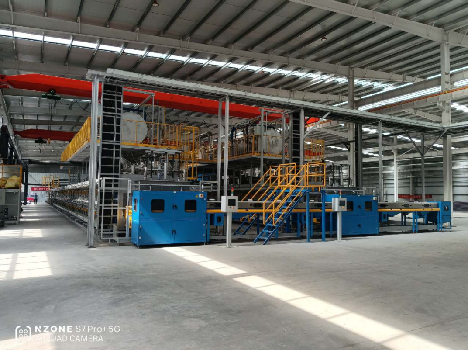

Typical Flowchart for Anode Material Made by Natural Graphite.

Grinding & Shaping

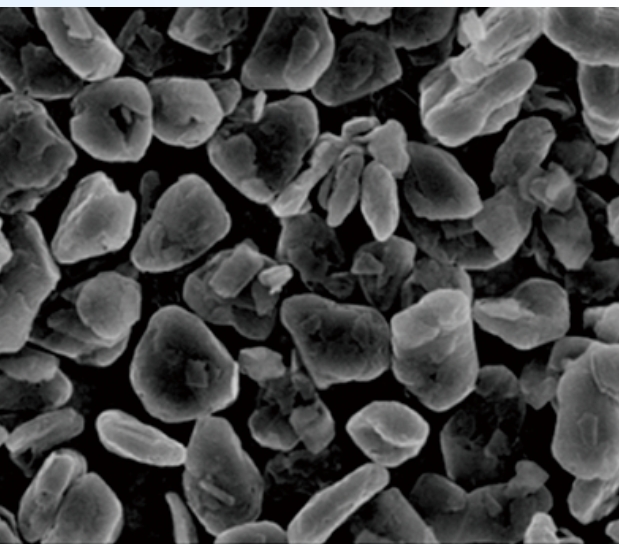

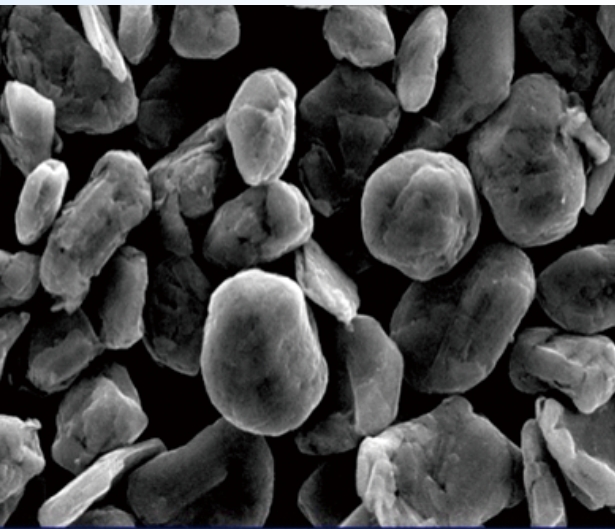

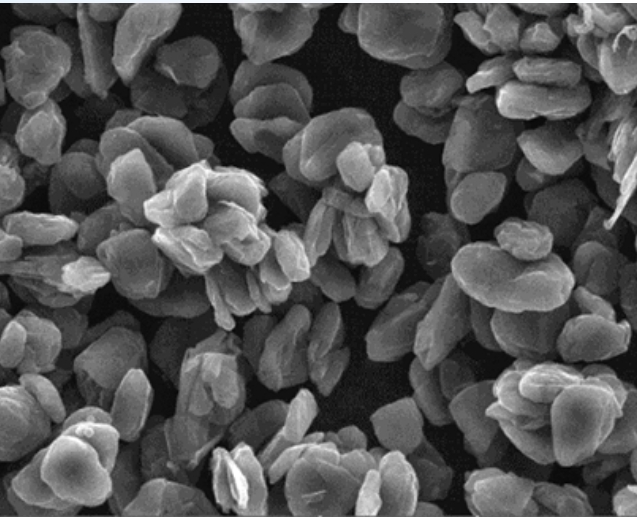

Spherical graphite is primarily manufactured using high-purity, high-carbon natural flake graphite as the raw material. The process involves plastic deformation of flaky particles through mechanical spheroidization, transforming their anisotropic sheet structure into near-spherical morphology.

Chemical Purification

Acid leaching is a widely used chemical method to purify natural graphite (typically 80–95% C) to ≥99% purity for applications like lithium-ion battery anodes.

Carbonization: purified natural graphite or natural graphite is uniformly mixed with pitch (pre-crushed to a specific particle size using specialized equipment) at a defined ratio in a high-speed mixer. The mixture is then transferred to a nitrogen-protected kiln for high-temperature carbonization at 1,200°C, where the pitch undergoes pyrolysis to form a carbon coating on the graphite surface.

Previous

Next

Previous:

Next:

MORE PROJECTS

Natural Graphite Anode Material