Artificial Graphite Anode Materials

May 06,2025

D50:

15.7

Tap D g/cm³:

1.04

(Cap)mAh/g:

≥359.4

(ICE)%:

≥94.0

Application:

Premium Smartphone & Long-Range Electric Vehicle (LREV) & Drone Battery

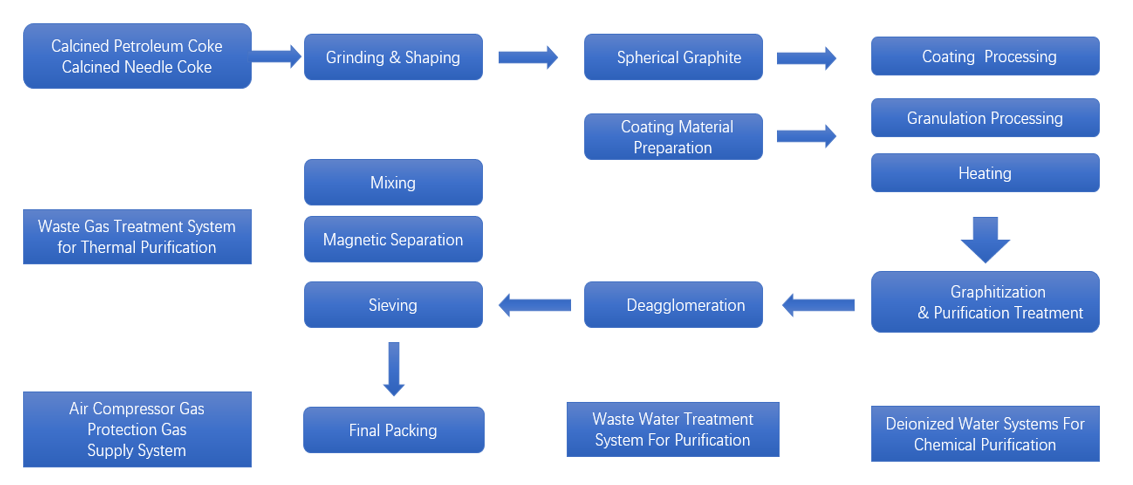

Typical Flowchart for Anode Material by Coke

Drying & Primary Crushing

- Drying: Due to the coarse particle size and high moisture content of raw materials supplied by vendors, pre-treatment steps—including crushing with a crusher and drying with a dryer—are implemented to ensure smooth feeding and stable production. The drying process is conducted under atmospheric pressure at temperatures ranging from 100 to 300°C, aiming to remove moisture from the raw materials.

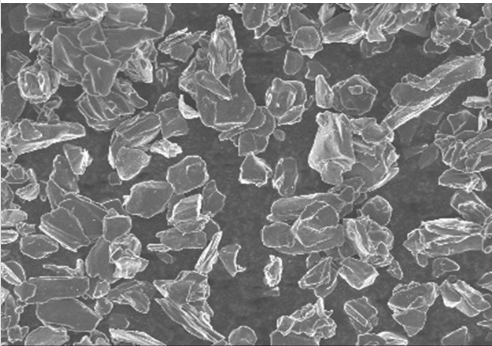

- Primary Crushing: The powder milling process involves ultra-fine mechanical grinding at room temperature under negative pressure, reducing raw materials from centimeter-scale to micrometer-scale. The micronized powder then undergoes precise classification via specialized high-accuracy grading equipment to remove fines and oversized particles, ultimately yielding powder materials with the designed particle size distribution.

Grinding & Shaping

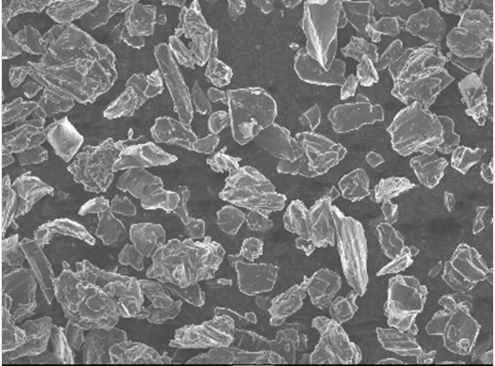

For classified powder materials, surface modification is further required to enhance the performance of anode materials (e.g., compaction). This process employs specialized shaping equipment for anode materials. Under ambient temperature and negative pressure, a high-speed rotating disk drives collisions between the material and stator, while dynamic/static heads integrate particle-to-particle friction and micro-filling of gaps to achieve shaping. The surface modification of micron-sized fine powder results in smoother particle surfaces, improved morphology, reduced specific surface area, and higher tap density, ultimately optimizing the final performance of anode materials

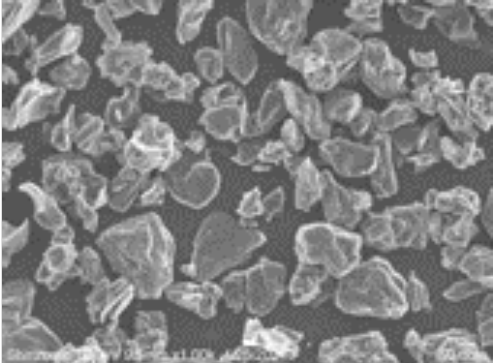

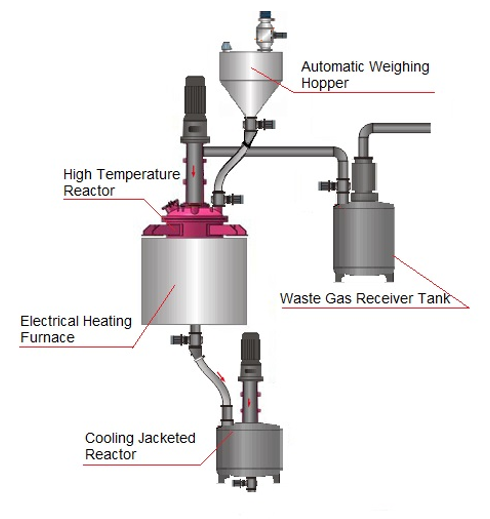

Coating & Granulation

Coating & Granulation: the process involves using a reactor to melt and bond pitch at controlled temperatures (300–800°C) over a specified duration, transforming primary particles into secondary agglomerates. The reactor operates under atmospheric pressure, serving to thermally activate the material while applying mechanical force to promote interparticle contact and fusion, ultimately yielding the desired secondary-particle-structured product.

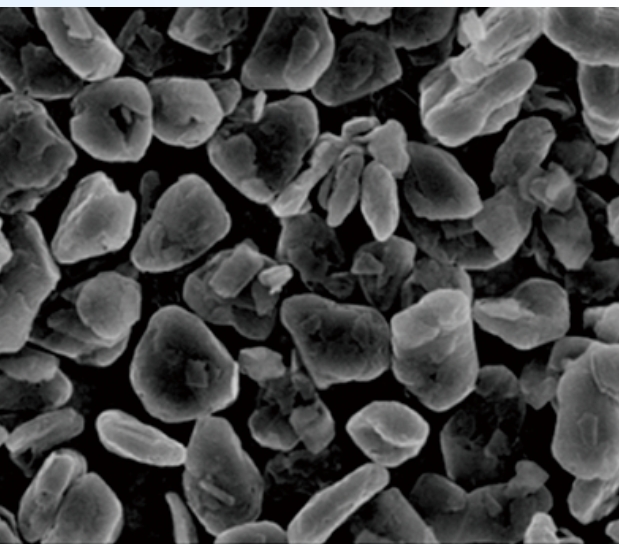

Graphitization

The graphitization of the anode material is that the intermediate product form low-temperature carbonization segement or the coating & granulation segment is heat-treated at a high temperature of 2800~3000 ℃, obtaining the physical and chemical properties required for artificial graphite anode materials. The design of this project adopts advanced technology routes and domestic advanced equipment to reduce the total energy consumption less than 11000 kWh by using larger volume DC Acheson furnace, through accurate power control, the average consumption of the semi -finished graphited product. Compared with the traditional consumption of 12000-14000kWh/ton, the annual power conservation of optimized graphitization is 25 million kWh. Apart from the Acheson furnace, we can also design the length-wise graphitization furnace and grid box graphitization furnace. For making the high end anode materials, the Acheson furnace is more stable and matur.

Carbonization

Carbonization: graphitized artificial graphite or natural graphite is uniformly mixed with pitch (pre-crushed to a specific particle size using specialized equipment) at a defined ratio in a high-speed mixer. The mixture is then transferred to a nitrogen-protected kiln for high-temperature carbonization at 1,200°C, where the pitch undergoes pyrolysis to form a carbon coating on the graphite surface.

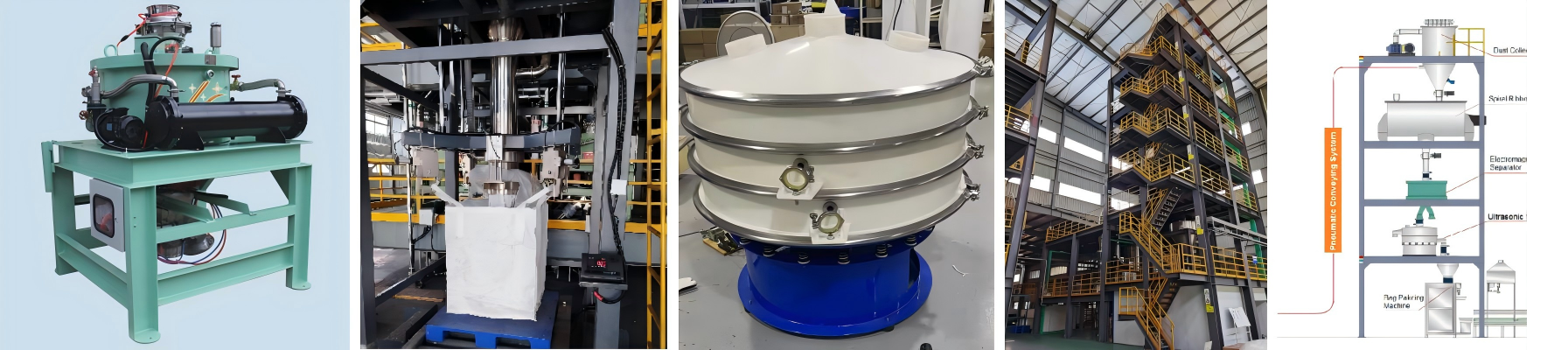

Product processing

Product processing & Warehouse: the material undergoes mixing, sieving, and magnetic separation at ambient temperature to remove oversized particles and magnetic impurities. After passing quality control tests, it is packaged according to customer specifications and stored in the finished goods warehouse.

Previous

Next

Previous:

Next:

MORE PROJECTS

Natural Graphite Anode Material